JBL Technical Note - Vol.1, No.33 电路原理图.pdf

JBL Technical Note - Vol.1, No.33 电路原理图.pdf

《JBL Technical Note - Vol.1, No.33 电路原理图.pdf》由会员分享,可在线阅读,更多相关《JBL Technical Note - Vol.1, No.33 电路原理图.pdf(8页珍藏版)》请在收音机爱好者资料库上搜索。

1、1. Introduction: JBL Professional introduced the Differential Driveconcept in the EON System in 1995 as a means of attaining maximum system perform- ance with minimum weight. Compared with tra- ditional driver designs, JBLs patented Differential Drive makes use of a pair of in-line voice coils in se

2、parate magnetic gaps instead of a single voice coil-gap combination. This permits a more effective use of available space, and allows more efficient removal of heat from the motor structure. Specifically, the voice coils are reversely wound and are immersed in magnetic fields of opposite polari- ty.

3、 This ensures reduced magnetic leakage flux and focuses more magnetic energy in the gaps where it is needed. Both ferrite and neodymi- um-iron-boron (NIB) magnets can be used, depending on the relative importance of weight in a given system design. When coupled with the light weight and high energy

4、density of NIB magnets, Differential Drive transducers can be constructed that are only about one-third the weight of traditional designs of comparable performance. Differential Drive provides many design options for the engineer. The size, impedance, and spacing of the two voice coils can be inde-

5、pendently adjusted relative to each other to attain a desired set of electromechanical per- formance features. Independently of these, the overall size and mass of a system can be adjusted as required. JBL has been granted numerous patents on multiple aspects of Differential Drive dual-coil, dual ga

6、p designs. We will compare the traditional approach with Technical Note Volume 1, Number 33 Title: JBLs Differential DriveTransducers Differential Drive technology in detail. 2. Anatomy of a Differential Drive transducer: The simplest way to understand Differential Drive is to compare it directly wi

7、th JBLs traditional motor structures. Figure 1 shows a section view of a tradi- tional JBL magnet-voice coil assembly and a Differential Drive system. As a starting point, let us design the Differential Drive system so that its parameters are identical to those of the traditional motor structure, wi

8、th the same electrical-to-mechani- cal coupling and the same moving mass. In the traditional design, magnetic flux density B crosses a gap in which a coil of wire of length lis placed. The coil has an electrical resistance, RE. These quantities establish the value of (Bl)2/RE, which is the electrome

9、chanical coupling factor of the driver. Now we inspect the Differential Drive topology. In this design there are two magnetic gaps that have opposing flux fields, and each gap has a Bfield equal to that of the traditional design. Two reversely- wound coils are used, each using wire with one-half the

10、 cross-section width as before. The coils are scaled so that they are one-half the length of the traditional coil. In addition, the masses of the two thinner coils will equal that of the single traditional coil. Each of these thinner coils will then have a coupling factor of 0.5(Bl)2/RE, or one-half

11、 that of the tradition- al driver. Since there are two such voice coils, both acting in the same direction, the total coupling factor for the new motor structure will be identical to that of the traditional design. This relationship is shown in Figure 2. 1 Figure 1. Comparison of standard and Differ

12、ential Drive technologies. Figure 2.The equivalence of standard and Differential Drive technologies. 2 In redesigning the system as shown here we have gained some significant design advan- tages: A. Better heat dissipation. The physical sep- aration of the two coils can be adjusted for optimum heat

13、transfer from each coil to the outer structure of the driver. In addition, the total surface area of the two coils has doubled, creating twice the heat radiation capability. B. The new voice coil arrangement will have lesseffective inductance than the standard one, since the reversely wound coils wi

14、ll have negative mutual inductance between them. This translates into a more uniform impedance curve and extended output at higher frequencies. C. The compact nature of the Differential Drive motor structure requires much less iron in the magnetic return path. If NIB (neodymi- um-iron-boron) magnet

15、material is used, a Differential Drive transducer can weigh as little as one-thirdthe equivalent traditional ferrite design. This advantage shows up primarily in overall system weight and ease of installation. D. The structure is inherently shielded mag- netically, especially at 90 degrees away from

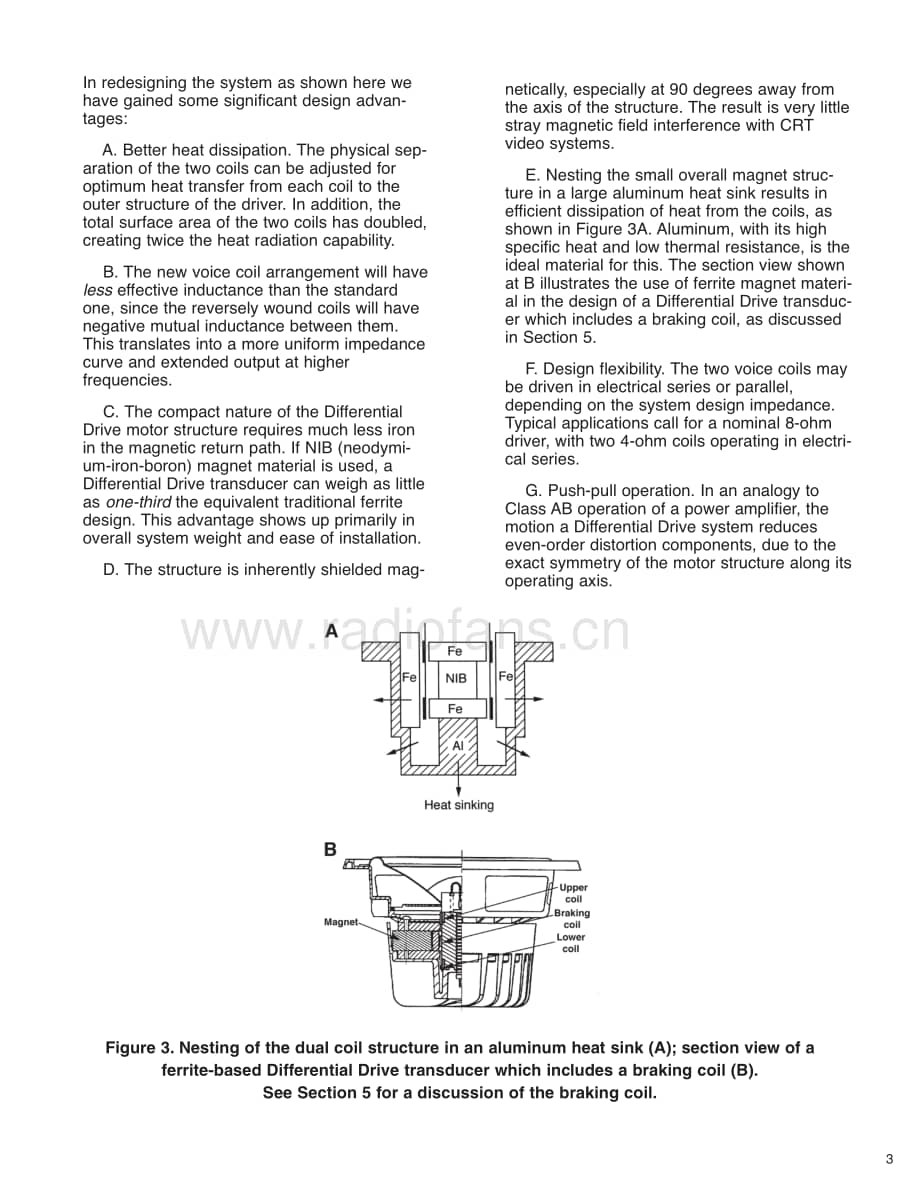

16、 the axis of the structure. The result is very little stray magnetic field interference with CRT video systems. E. Nesting the small overall magnet struc- ture in a large aluminum heat sink results in efficient dissipation of heat from the coils, as shown in Figure 3A. Aluminum, with its high specif

17、ic heat and low thermal resistance, is the ideal material for this. The section view shown at B illustrates the use of ferrite magnet materi- al in the design of a Differential Drive transduc- er which includes a braking coil, as discussed in Section 5. F. Design flexibility. The two voice coils may

18、 be driven in electrical series or parallel, depending on the system design impedance. Typical applications call for a nominal 8-ohm driver, with two 4-ohm coils operating in electri- cal series. G. Push-pull operation. In an analogy to Class AB operation of a power amplifier, the motion a Different

19、ial Drive system reduces even-order distortion components, due to the exact symmetry of the motor structure along its operating axis. 3 Figure 3. Nesting of the dual coil structure in an aluminum heat sink (A); section view of a ferrite-based Differential Drive transducer which includes a braking co

20、il (B). See Section 5 for a discussion of the braking coil. Figure 4. Flux modulation in ferrite and NIB magnet structures. 4 4. Performance of Typical Drivers: The transducers in all of these curves are mounted in a 280-liter (10 cu. ft.) sealed enclo- sure. Low-frequency response and distortion pe

- 配套讲稿:

如PPT文件的首页显示word图标,表示该PPT已包含配套word讲稿。双击word图标可打开word文档。

- 特殊限制:

部分文档作品中含有的国旗、国徽等图片,仅作为作品整体效果示例展示,禁止商用。设计者仅对作品中独创性部分享有著作权。

- 关 键 词:

- JBL Technical Note Vol.1 No.33 电路原理图 Vol No 33 电路 原理图

收音机爱好者资料库所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

收音机爱好者资料库所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

Marshall-9100-62-02-Schematic电路原理图.pdf

Marshall-9100-62-02-Schematic电路原理图.pdf